Professor Lucas Hof and his research team have developed a Sustainable Composites from Waste Eggshells with improved thermal, mechanical and biodegradable properties. Read a summary of their research in circular economy.

Summary

Additive manufacturing (AM) is a promising avenue to support the transition to a more circular manufacturing model. As a result, research to develop new, sustainable and high-performance materials for AM has gained interest in recent years. However, additional efforts are needed to achieve this goal, as there is still much room for improvement. A common method to modify the mechanical properties of polymeric materials is to add reinforcements, either continuous or short. Different fibers, powders or particles can be used as reinforcement. In the case of reinforcing particles, their size, morphology, surface characteristics, chemical composition and quantity in the mixture all play an important role in the resulting mechanical properties. In addition to having an impact on the mechanical properties of the parts produced, the type and amount of reinforcement particles added to the mix has an impact on the manufacturing process and the recycling potential of the parts produced. As the different polymers and reinforcements all have their own particularities, it is essential to proceed by analysis and experimentation to formulate an ideal blend. The polylactic acid (PLA)-eggshell blend has already been evaluated for more traditional processes such as hot pressing, injection molding, compression molding and film casting, but not for AM. PLA is a good candidate since it is a biopolymer and is also the most widely used material in AM.

The main objective of this research is to evaluate the potential of using an organic waste material, such as chicken eggshells, as reinforcing particles to improve the mechanical properties of 3D printed PLA samples without compromising recyclability.

In order to evaluate the mechanical properties, manufacturing process impacts, and recyclability of parts additively produced with PLA-eggshell composites, several tests and analyses have been conducted. To date, these tests and analyses have evaluated:

- Flexural properties (ASTM D790)

- Tensile properties (ASTM D638)

- Thermal behavior (DSC)

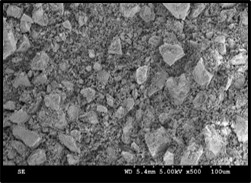

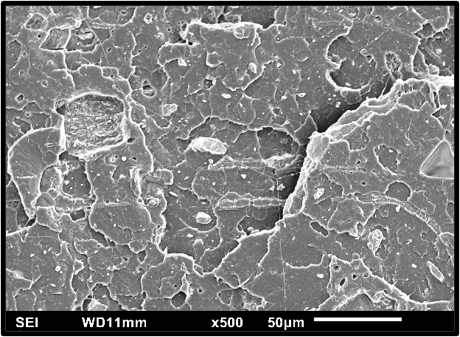

- Particle morphology (SEM)

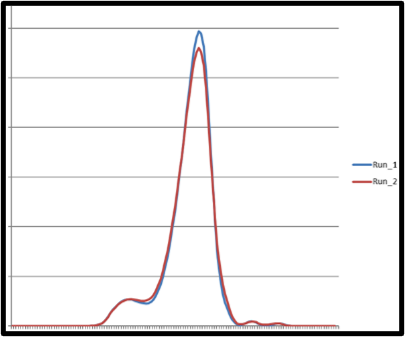

- Particle size distribution (PSD)

- Flow characteristics (Capillary Rheometer)

These tests were carried out for pure PLA and for blends with 5, 10 and 20 % (w/w) of ground eggshells in powder form, respectively. Comparison tests, with specimens containing mineral limestone particles instead of eggshells were also carried out due to the similarity of chemical composition, but with differences in particle size and morphology. Figures 1 and 3 show images obtained with a scanning electron microscope (SEM). Figure 1 shows the eggshell particles used in our composites and the graph in Figure 2 shows their size distribution. Figure 3 shows the fracture surface of a composite specimen with 5% (w/w) eggshells that failed in tension.

The specimens used to perform the mechanical tests will be crushed and then re-extruded into filament and re-printed into specimens. This cycle will be repeated several times in order to evaluate the degradation of mechanical properties related to recycling.