Professor Lucas Hof and his research team have developed a new recyclable raw material for 3D printing. Read a summary of their research in circular economy.

Summary

Additive manufacturing, or 3D printing, is a process that engineers can use to create new and unique designs quickly. While AM is well-established for polymer materials like PLA and ABS, incorporating metals into AM has been difficult due to expensive equipment for 3D printing of pure metals or due to difficulties of metal incorporation into a polymer matrix and the creation of metal/polymer filaments with high metal content. In addition, once a green metal/polymer part is printed, debinding and sintering are critical steps in reaching of final product. Developing a good debinding and sintering process is crucial for achieving high-quality parts with good mechanical properties. The debinding process must remove the binder completely without damaging the green part, while the sintering process must fuse the metal particles together evenly without causing distortion or cracking. Factors such as temperature, time, atmosphere, and heating rate must be carefully controlled to achieve the desired properties.

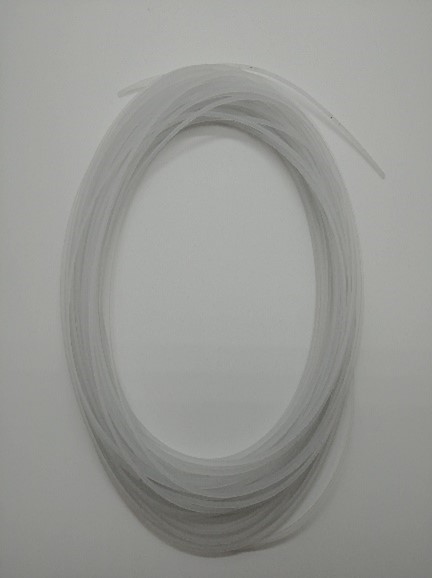

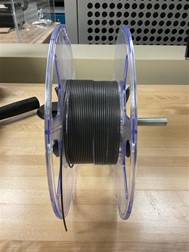

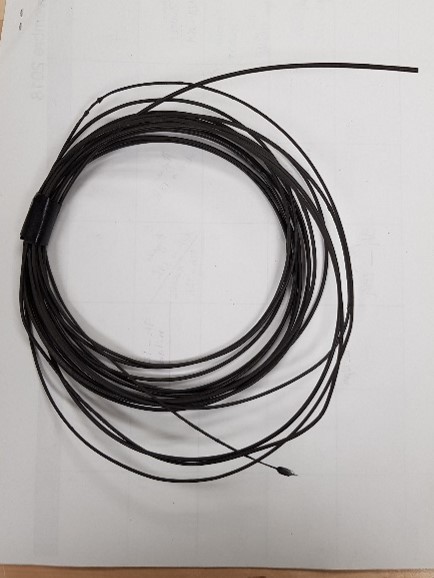

Hence, the primary objective of this research project is the development of metal-infused filaments containing high concentrations of environmentally friendly extracted carbonyl nickel (Ni) and carbonyl iron (Fe) powders together with recyclable and bio-based polymers as potential matrixes in order to use it in standard 3D printers. To make the filaments, a simple melting process with a single screw extruder was used. The figures below illustrate the produced pure polyethylene (PE), PE/Ni and polylactic acid (PLA)/Ni filaments. To ensure that the filaments are recyclable, re-extruding and repeating the production process until significant mechanical performance loss is observed will be performed in a next step. This will provide information about the recyclability of the developed 3D printer feedstock. Finally, 3D printing using the developed metal/polymer filaments and testing of the printed parts’ mechanical properties after debinding and sintering to produce dense metallic 3D freeform parts will be conducted.