Teams from ETS and Vestechpro, led by Lucas Hof and Ennouri Triki respectively, have analyzed the mechanical properties of a concrete incorporating used textile fibers. Read a summary of their work.

Summary

In the context of sustainable development, many sources of waste are being studied for re-use. Such is the case with manufactured textile products, whose excessive consumption has caused global fiber production to double over the past 10 years. Recycling these products by converting them back into fibers therefore seems an opportunity worth seizing. The construction industry uses virgin fibers to provide protection against cracking, greater compactness, improved tensile strength and ductility to cementitious materials. The Vestechpro research center has developed a process for obtaining fibers from textile waste (post-consumer and post-industrial), and wanted to explore the various potential applications of this recycled material by incorporating it into a cementitious matrix. The mechanical behavior and durability of such a composite material depend on the nature of the fibers used, their dimensions, morphologies and dosage.

The main objective of this study is to explore the effect of fibers derived from the mechanical recycling process developed by the Vestechpro research team. To this end, a mortar was formulated to incorporate these fibers without losing its workability. A cementitious material was mixed with the recycled fibers to obtain a mortar with 0.33% fiber by volume. Three different commercial virgin fibers were also used for comparison purposes. These commercial fibers are polypropylene, while the recycled fiber is polyester.

The effects of recycled fiber and its commercial competitors on mortar were investigated from several aspects using various methods, some of which were specially developed for this study:

- Flexural strength

- Compressive strength (ASTM C109)

- Thermal conductivity (MTPS)

- Fiber dispersion in mortar

- Air drive

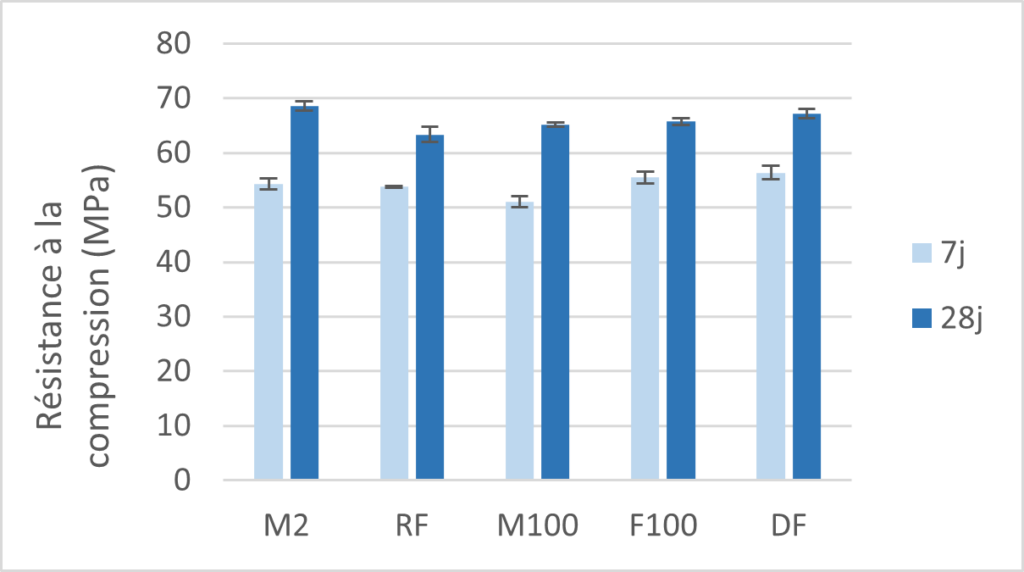

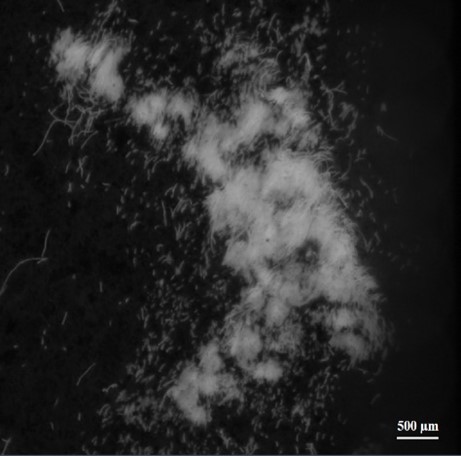

The mechanical bending and compression results confirm that, at mortar scale, recycled fiber has no deleterious effect on the material. Performance was comparable with that of its competitors. Figure 1 shows compression results at 7 and 28 days for mortar alone (M2), recycled fiber (RF) and commercial fibers (M100, F100 and DF). Furthermore, the thermal conductivity of mortar including recycled fiber is not particularly low, a result expected for the dosage and comparable to commercial fibers. Observation of the dispersion of recycled fibers highlighted a problem associated with the recycling process: pieces of fabric still woven among the fibers. Figure 2 shows a microscopic observation of this defect. This undoubtedly explains the greater quantity of air entrained in the mortar with recycled fibers.

In order to ensure that the recycled fiber obtained with Vestechpro’s fraying machine is as effective as its competitors, it remains to assess its ability to prevent cracking and validate its durability.